The original modular hose

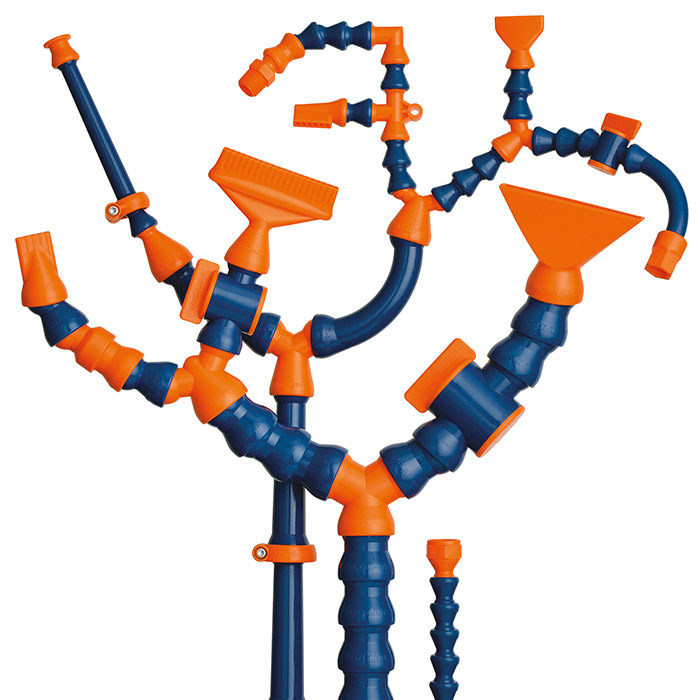

From the characteristic orange-blue color, constructed with a special acetyl polymer chemically resistant to petroleum, coolants, and most common chemicals, the Loc-Line can be mounted on all machine tools and used for the passage of water, oil, and air. The base of the system is an assemblable element capable of forming a flexible tube that offers unlimited positioning and perfect liquid flow.

Why choose LOC-LINE

- Positionable in any direction

- Absolutely airtight

- With no internal core that could interrupt the flow

The magic of Loc-Line

Since 1983, the Loc-Line system has been the answer to a specific problem in machine tools: how to get coolant to the tool when it comes into contact with the material. The design is simple and elegant. The base of the system is an assemblable element that forms a flexible tube offering unlimited positioning and perfect liquid passage. Effortless and mouldable by hand, it stays in place and can be positioned according to any processing requirement. Bends do not change the inner diameter and Loc-Line does not twist like a copper tube. Unlike metal tubes, Loc-Line does not damage the tool in the event of contact and does not conduct electricity: it is ideal for EDM machines. Easily repositionable and extremely rigid, it is not affected by machine vibrations. A specific line has been created to resist the most aggressive acids. All Loc-Line elements are marked.

Technical specifications

Acetalic

Colors: blue, orange, black, white, gray

Colors: blue, orange, black, white, gray

- Chemical compatibility:

- Yes: acetone, alcohol, ethyl, fats, oils, commercial dishwashing detergents, petrol, paint solvents, sodium hydroxide

- Not: chlorine, acids, ammonium hydroxide, strong bases, hypochlorite ion solutions, sodium hypochlorite

- melting point 329°F

- Maximum operating temperature: 170F (repeated exposure to this temperature will cause fatigue)

- Recommended maximum line pressure and flow rates:

- System 1/4″: 50 psi – 250 gph or (110 psi – 500 gph with element clamps)

- System 1/2″: 30 psi – 475 gph or (60 psi – 950 gph with element clamps)

- System 3/4: 20 psi 1,140 gph or (40 PSI 2,280 gph with element clamp)

- Acetal Copolymer in compliance with the regulations in 21CFR 177.2470 meets the requirements of this regulation for contact with foodstuffs.

- All dyes are used at the recommended reduction ratio to meet 21CRF 178.3297.

- Loc-Line is not approved for use with alcoholic or fatty foods at any temperature.

- This material meets international standards NSF 14, 51 and 61 for contact with potable water

- Please note that all applications have variables and conditions that will affect maximum working pressures. It is always advisable to test for suitability for your application.

- Lockwood Products Inc. does not guarantee any particular application for its products.

Loc-Line for acid

Colors: Yellow

Chemical compatibility:

Chemical compatibility:

- YES: acids below 150F, alcohols, aromatic solvents, petrol, grease, hydrocarbons, oils, salt

- Not: acid up to 150F, chlorine, acetone, chlorinated hydrocarbons, strong bases, ethyl acetate, water warmer than 150F

- Melting point: 475F

- Max temperature: 170F (repeated exposure to this temperature will cause fatigue)

- Recommended maximum line pressure and flow rates:

- System 1/4″: 50 psi – 250 gph or (110 psi – 500 gph with element clamps)

- System 1/2″: 30 psi – 475 gph or (60 psi – 950 gph with element clamps)

- System 3/4: 20 psi 1,140 gph or (40 PSI 2,280 gph with element clamp)

- Acetal Copolymer in compliance with the regulations in 21CFR 177.2470 meets the requirements of this regulation for contact with foodstuffs.

- All dyes are used at the recommended reduction ratio to meet 21CRF 178.3297.

- Loc-Line is not approved for use with alcoholic or fatty foods at any temperature.

- This material meets international standards NSF 14, 51 and 61 for contact with potable water

- Please note that all applications have variables and conditions that will affect maximum working pressures. It is always advisable to test for suitability for your application.

- Lockwood Products Inc. does not guarantee any particular application for its products.